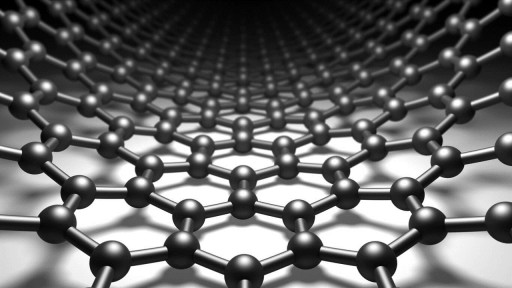

Sheet of Graphene

Render of a sheet of graphene

MELBOURNE, Australia - March 16, 2022 - (Newswire.com)

Since the discovery of graphene in 2004, and the award of the Nobel Prize in 2010 to Geim and Novoselov, the wonder material graphene has shown great potential for solving the global water crisis. Over the past 5 years, Clean TeQ Water (ASX:CNQ) subsidiary, NematiQ, has been singularly focused on achieving a scalable manufacturing process to produce graphene-based nanofiltration membranes for water treatment.

Direct Graphene Membrane nanofiltration technology is a giant leap forward in producing pure and affordable water. NematiQ's Graphene Membranes are designed to remove bacteria, virus and dissolved organic compounds without removing the salts.

The global market for membrane-based water filtration, including micro, ultra, nano and reverse osmosis, is estimated at more than USD$18 billion annually and the addressable market for Graphene Membranes is estimated at USD$5 billion. Over the years, Clean TeQ Water has invested significant funds in developing a Graphene Membrane for this highly lucrative membrane market.

NematiQ has now achieved a major milestone by producing over 1,000m of 1,000mm wide flat sheet Graphene Membrane, at speed, on an industrial roll-to-roll coating machine, confirming the ability to manufacture Graphene Membrane at commercial scale.

Some of the many benefits of the Graphene Membrane include less energy use, high water recovery and less by-product. Graphene Membranes also have superior anti-fouling properties and so use considerably less chemicals to clean than the commonly used polymeric membranes.

Graphene Membrane nanofiltration has potential applications in many areas of water and wastewater treatment and industrial separations, including treatment of water for drinking, pre-treating seawater prior to desalination, recycling of grey water, treatment of municipal and industrial water for reuse and for separation of high value products, for example, in the food and pharmaceuticals industries.

The Graphene Membrane has achieved the benchmarks for permeance and rejection, confirming the energy efficient nanofiltration membrane removes contaminants such as dissolved organics for a range of feed waters.

The Graphene Membranes will now be converted into spiral wound cartridges. These cartridges will be incorporated into demonstration treatment plants, the final step before commercial sales of the membranes can begin.

For more information visit www.nematiq.com.

Willem Vriesendorp

CEO and Investor Relations

+61 3 9797 6700

info@cleanteqwater.com

www.cleanteqwater.com

Related Images

Sheet of Graphene

Render of a sheet of graphene

NematiQ Graphene Membrane

Roll of NematiQ Graphene Membrane

NematiQ Portable Pilot Unit

Portable pilot unit containing NematiQ Graphene Membrane

Press Release Service by Newswire.com

Original Source: Groundbreaking Graphene Membrane Manufactured at Commercial Scale